If you see a pic that isnt tagged please report. We are, by default an adult community but plenty of adults are squeamish. Be it machine gore or how you sliced your finger off on a bandsaw. Posting gory or gruesome pictures is totally fine. If you see this behavior taking place in a thread, please report it so that the moderation team can remove the offending posts.

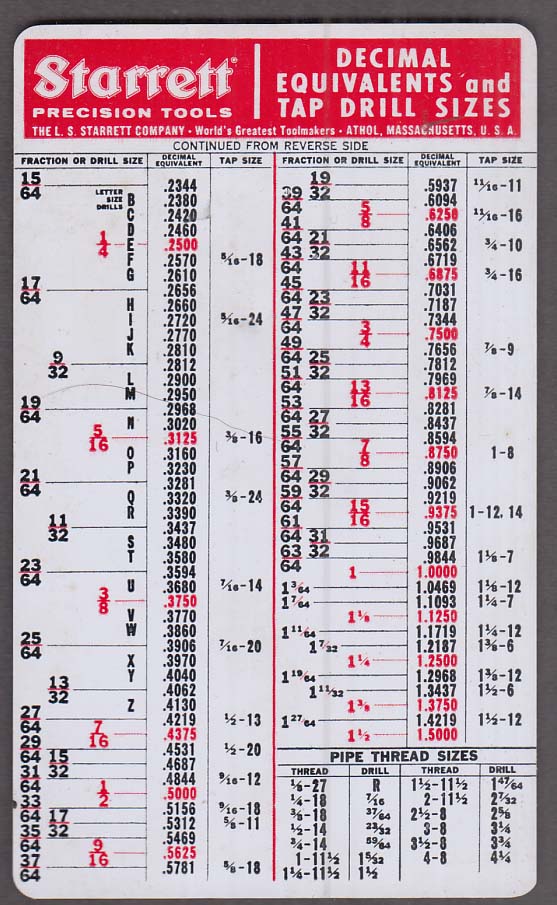

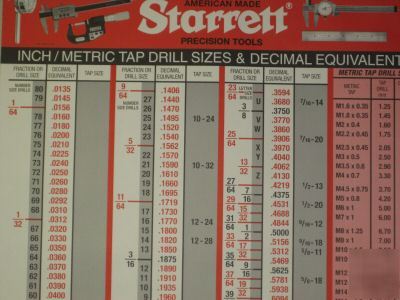

You don't have to like the way that someone else drills a hole, but there is absolutely no reason to personally attack, harass or insult another user. Facebook Twitter Instagram Youtube Linkedin. Have some pride in your specialty, and set your flair on the sidebar to declare your area of expertise!īe polite. We decided to make a drill chart for our followers This chart breaks down all major standard and metric drill sizes with roll and cut tap options. Just remember to wash your hands before and after you go to the bathroom.įor anything tooling related, from belt grinders to Bridgeports to CNC programming. The thread or threading on the sides of the hole is needed to hold the screws or bolts in place.Break out your Gerstner and get to work. PRICE: 55 Starrett Pocket Reference Cards Double sided 3' x 5' cards for quick conversion between Fractional Inches, Metric and Decimals as well as Tap Drill sizes. Drill Bits come in many sizes and shapes. When it comes to drill bit sizes, there at least 153, those are the ones I can recall right now, there could be more, hence the need for a drill size chart with thread information.Ī drill bit is a cutting tool which purpose is to remove material to create a hole, it will most likely always be a cross section circular shape. Determining the drill bits and taps to use is a taxing feat for every engineer. The modern-day design engineer utilizes up-to-date tap drill charts to machine threads and holes with great accuracy and efficiency.

#Drill tap chart starrett free

While there are common threads like the American pipe thread, the unified thread there are many unfamiliar threads. 20 Free Tap Drill Charts (PDF) High precision is a must-have in machining operations in today’s engineering industry. The proliferation of fittings and connectors makes correct thread identification a difficult and exhausting task even for the most experienced technician or mechanical engineers there’s always a new thread out there. A drill size chart contains drill sizes and thread data that is so large that is almost impossible for a mechanical engineer to remember it all. Press down and turn the tap inside the hole and then the tap cuts the thread. Table of Contents Show Tap is required to make female screw threads. However, the particular drill chart is essential for sizes of the drills only. Often it is the corresponding dies and taps that you see together when buying either ones. Starrett Tap Drill Chart The Home Shop Machinist - Tap Drill Chart - Physics Instrument Shop:Tap Drill Chart By : Carpentry Metal Working Tools Metal Lathe Tools Tap Chart Chart Tool Garage Tools Garage Shop Garage Workshop Drill Guide.

Ensure that the tap is positioned in a perpendicular direction to the hole. A tap drill chart is key in matching pairs of female and male thread that tightly secure together. Now, place the tip of tap inside the hole. Next, on the top of the holder, position the square and tighten it. The best thing to do is find a tap drill clearance chart you can print, just like the one we offer in this article and print it for your lab so your team can easily access it. For this, look at the tap drill chart to find the correct size and start drilling. You might be interested in: DFM Electronics Guidelines

#Drill tap chart starrett pdf

You can find a drill and tap chart pdf here it’s a completely free printable tap drill chart that we hope can help you in your operations. Reading a tap drill chart is simple, taking our tap drill size chart as an example, simply scroll through the left-hand column and find the tap drill size you need, on the right you’ll find a column with the drill bit you need. For Imperial (inch) threads the tapping drill size is calculated in the same way, diameter minus pitch. 75 thread the tapping drill is 5-0.75mm = 4.25mm. 75% Thread for Aluminium, Brass, & Plasticsįor Metric threads, you can calculate the tapping drill by subtracting the pitch from the diameter of the thread.

0 kommentar(er)

0 kommentar(er)